Helping Ensure AM Parts Are Safe For Use

Additive manufacturing is pushing the limits of metallurgy to a whole new level, allowing rapid production of parts as-needed. Our metallurgical experts can help you optimize, test, and ensure the quality of your A.M. components. We help you interpret and use the result of additive manufacturing testing to further improve products and save money. We help apply a combination of science and engineering to produce real results.

What Corrosion Tests Are Needed for Additive Manufacturing Parts?

The corrosion requirements for additive manufactured parts depends on the applications and associated requirements. For some components, a simple tensile test and/or microstructure analysis are sufficient. For other components, much more detailed analysis like fracture toughness, fatigue, or electrochemical corrosion testing are necessary.

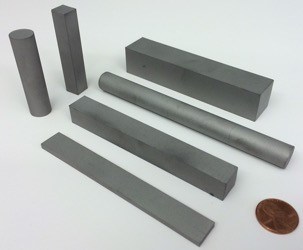

Additive Manufacturing Metallurgical Analysis

AM parts fall somewhere between cast and weld microstructures, which can vary widely depending upon the process and parameters. Our metallurgical experts can help with deep metallurgical and microstructure analysis to help you optimize and improve your AM components.

What Corrosion Testing is Best for Additive Manufacturing?

Our corrosion experts offer an enormous range of corrosion tests that are appropriate for additive manufacturing. A short list of examples includes:

- ASTM Corrosion Testing

- NACE Corrosion Testing

- Accelerated Environmental Cracking Analysis

- Hydrogen Embrittlement Testing

- Electrochemical Testing

- Sour Corrosion Testing

Our corrosion and metallurgy experts are ready to help. Contact us now:

AM Fatigue and Cracking Testing

Additively manufactured parts experience very complex thermal cycles. AM parts may have much different environmental cracking and fatigue life susceptibility than traditional materials. US Corrosion offers rapid assessment capabilities for fatigue, stress corrosion, and other cracking mechanisms. Let’s talk!