Environmental cracking includes a broad range of cracking mechanisms, including stress corrosion, hydrogen embrittlement, corrosion fatigue, and sour stress corrosion. Often the failures from these mechanisms can take months or years to occur, and most of the common accelerated testing techniques still take months or years for the testing. At US Corrosion, though, we utilize the rising step load (RSL) testing methods to evaluate these same mechanisms in a matter of days or hours. For the first time, testing can be performed on a schedule that doesn’t interfere with production.

What is ASTM F1940 Used For?

ASTM F1940 is one of the standard processes for testing metals to prevent internal hydrogen embrittlement of steels by coating or plating processes. Hydrogen embrittlement (HE) requires hydrogen, stress, and a susceptible material. Either incremental step loading (rising step loading) or sustained loading are used to confirm that the residual hydrogen is not enough to cause embrittlement in a possibly susceptible material.

How does Hydrogen Embrittlement Occur?

Hydrogen is introduced into materials during fabrication, coating, plating, cleaning, and other processes. As strength and/or stresses increase, the amount of hydrogen necessary to result in embrittlement decreases dramatically. For example:

- Low-strength steels can accommodate dozens or hundreds of parts per million (ppm) of hydrogen without being susceptible to HE.

- High-strength steels can sometimes only have 2-3 ppm of hydrogen and still be embrittled.

- Incremental aka rising step loading provides a quantitative measure of hydrogen embrittlement susceptibility of materials.

Is Incremental Step Loading or Sustained Loading Better?

The incremental step loading (ISL aka rising step load)method is preferred as it rapidly provides a quantitative measure of hydrogen embrittlement susceptibility. Each test provides an accurate, reproducible, and quantitative measure of the effect of hydrogen for each heat or batch of materials. ISL/RSL is also a much faster method for hydrogen embrittlement testing which takes hours instead of days, reducing the bottleneck that can occur with high-strength alloys.

Consulting for ASTM F1940 Tests

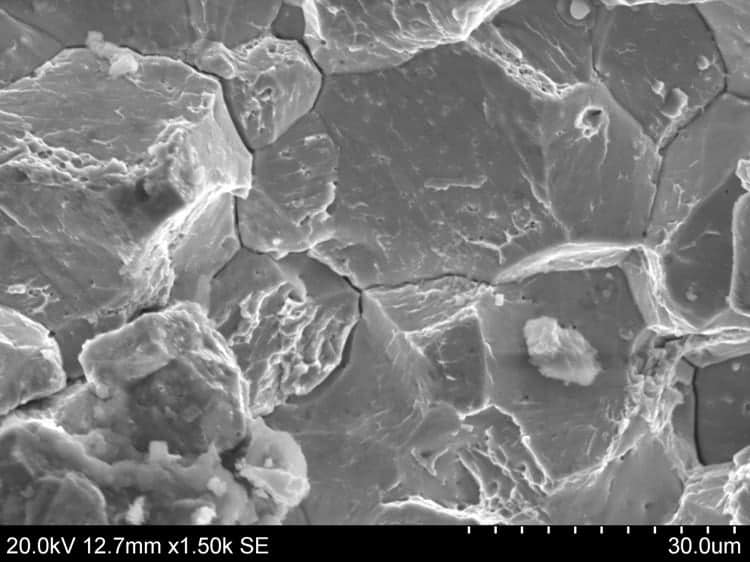

Our team has been involved in ASTM F1940 since the first draft of the method, and we remain highly active in the committee today. We use that experience to help many companies with questions regarding ASTM F 1940 and similar HE testing. Whether it’s design of experiments, interpretation of results, or detailed metallurgical inspection, we can help. For example, the electron microscopy below shows a classic intergranular fracture surface that’s often associated with hydrogen embrittlement.

Accelerated Stress Corrosion Cracking Analysis

Beyond hydrogen embrittlement, our system can also be used for SCC testing. Typical tests for stress corrosion cracking (SCC) can take from a week to a month or more – and then you only get a pass/fail answer at a given stress level. Utilizing the patented RSL method, US Corrosion offers rapid SCC analysis that can be completed in as little as one day. We also provide the stress corrosion testing equipment that you can install in your facility if you want to routinely test samples at your site.

How do You Perform Rapid Hydrogen Embrittlement Testing?

In the example below, 3″ bolts were tested to evaluate hydrogen embrittlement susceptibility. The testing samples in the center are show as they will be tested, with the bolt threads being placed in tension by bending. This much more accurately replicate the actual load that the bolts would experience in service. Many specimens can be removed from a single bolt, allowing for testing at various cathodic protections levels or in different chemical solutions (cleaning chemicals, saltwater, etc.).

The beauty of this method is that the tests can be performed with representative samples in a matter of hours or days, in comparison to other techniques that take weeks or months.

We’d love to help with your accelerated environmental cracking analyses – contact us today to get started!