Accurate and Rapid Hydrogen Embrittlement Testing

Hydrogen embrittlement occurs when too much hydrogen is absorbed in certain metals during production, coating/plating, or in service. ASTM F1624 testing is the fastest quantitative method for evaluating hydrogen embrittlement in new or used parts. US Corrosion is a leader in ASTM F1624 hydrogen embrittlement testing services and equipment.

We provide extremely accurate displacement-controlled F1624 analysis, which provides precision analysis of hydrogen embrittlement susceptibility. The old style of evaluating hydrogen embrittlement (sustained load testing) requires 200+ hours of testing time at a given load – and then you only get a pass/fail answer! In comparison, our F1624 gives highly accurate and reproducible data that provides an exact quantitative

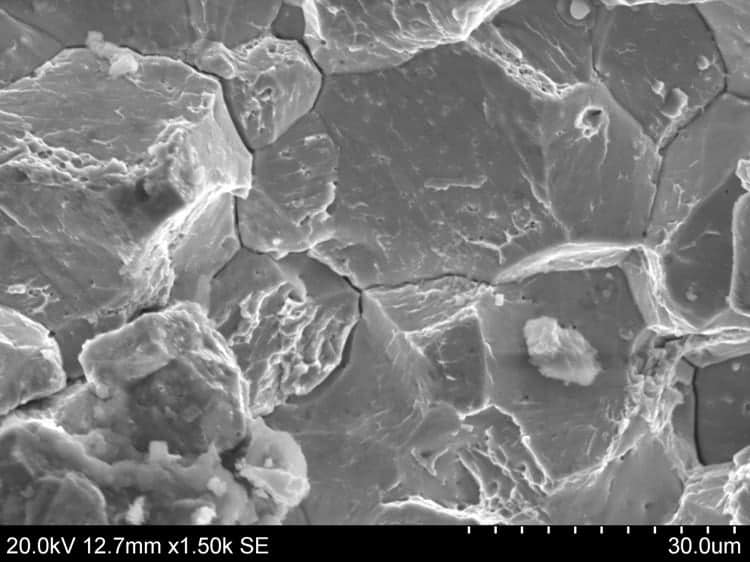

Our experts can also help you evaluate suspected hydrogen embrittlement failures, and duplicate the conditions where the failure occurred. We provide a wide range of other laboratory services, like the electron microscopy below that shows what a hydrogen-embrittlement failure often looks like:

ASTM F 1624 Corrosion Testing

US Corrosion provides rapid testing per ASTM F1624 and related methods to evaluate hydrogen embrittlement. We utilize multiple hydrogen embrittlement testing frames to ensure we can test many samples at once if needed.

ASTM F1624 Testing Equipment – US Corrosion manufactures the RSL testing equipment that is pre-programmed for testing per ASTM F1624 and other related methods. For plating shops, we provide a rapid method for ensuring every lot you produce is in good condition. For steel producers, researchers, and others, we provide a customized testing pattern based on different hardness ranges of materials.

Can ASTM F1624 Tests Measure Fracture Toughness?

Absolutely! One of the advantages of ASTM F 1624 is that it can determine a wide range of fracture toughness values, both in air and in simulated environments such as water, saltwater, and other fluids. Varied voltages can also be applied to simulate cathodic protection, or to pre-charge the samples with hydrogen before testing.

ASTM F1624 Testing By US Corrosion

At US Corrosion Services, we specialize in providing comprehensive and reliable hydrogen embrittlement testing services using the ASTM F1624 standard. Our team of experts is dedicated to delivering accurate and rapid testing solutions to help you ensure the safety and reliability of your materials.

Hydrogen embrittlement is a critical concern in various industries, including aerospace, automotive, oil and gas, and more. It occurs when hydrogen atoms penetrate the metal structure, leading to reduced ductility and increased susceptibility to cracking and failure. Timely and accurate testing is essential to identify and mitigate the risks associated with hydrogen embrittlement.

What Other Tests Supplement ASTM F1624?

Additional Services – in addition to F1624 testing, US Corrosion also offer related ancillary services like optical and electron microscopy, hardness and tensile testing, consulting services, and more.