API 571 and similar documents provide the framework for how damage mechanism assessment (DMA) works – and our engineers provide the expertise to help you make sure you implement it correctly. Whether it’s analysis of a single item or a whole facility, we can help with DMA, fitness-for-service calculations, risk-based inspection, and implementation of a mechanical integrity program.

What is a damage mechanism?

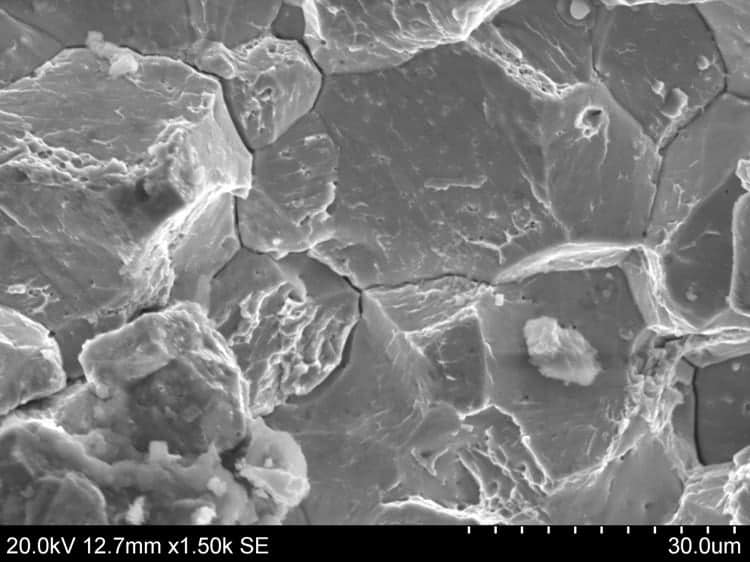

A damage mechanism is any type of potential cause of failure, problems, or corrosion. There are many potential damage mechanism, including forms of corrosion and cracking, thermal damage, wear and abrasion, and even radiation. By understanding all of the possible damage mechanisms, you can then evaluate their likelihood and determine how to best approach each one. Basically, a damage mechanism is one particular way a system can fail to perform.

What do I do once I know the potential failure modes?

The next step is to evaluate their likelihood of occurring, and then incorporate the damage mechanisms into a mechanical integrity program with an effective inspection strategy. Numerous industry codes exist to help with establishing the appropriate inspection intervals for different damage mechanisms, such as API 510, 570, 571, 579, 580, 581, and 653. At this point, you’ll want to involve a metallurgist and/or corrosion expert to help you evaluate the most likely mechanisms in your particular applications.

Which damage mechanisms are likely?

API RP 571 is an excellent guide for refineries and chemical processing facilities, which includes over 60 of the most common damage mechanisms. In a large facility, 50 or more may be possible, and development of the mechanical integrity program may be a multi-month or even year-long process. For a specific piece of equipment, anywhere from 2-20+ damage mechanisms are possible. Therefore it’s important to have someone with experience and training help you during DMA to identify the most likely mechanisms along with appropriate inspection methods.

Some common mechanisms include:

- Pitting Corrosion

- High-Temperature Hydrogen Attack

- Hydrogen Embrittlement

- Stress Corrosion

- Sour Corrosion

- Hydrogen-induced Cracking

- CO2 Corrosion

- Sulfidation

- Brittle Fracture

- Oxidation/Rust

Our experienced corrosion engineers have the knowledge needed to help you accurately evaluate your facility and optimize your maintenance operations.

Ready to get started? Contact us: (or call 832-481-6600 to reach us now!)