Houston Welding Consulting Laboratory

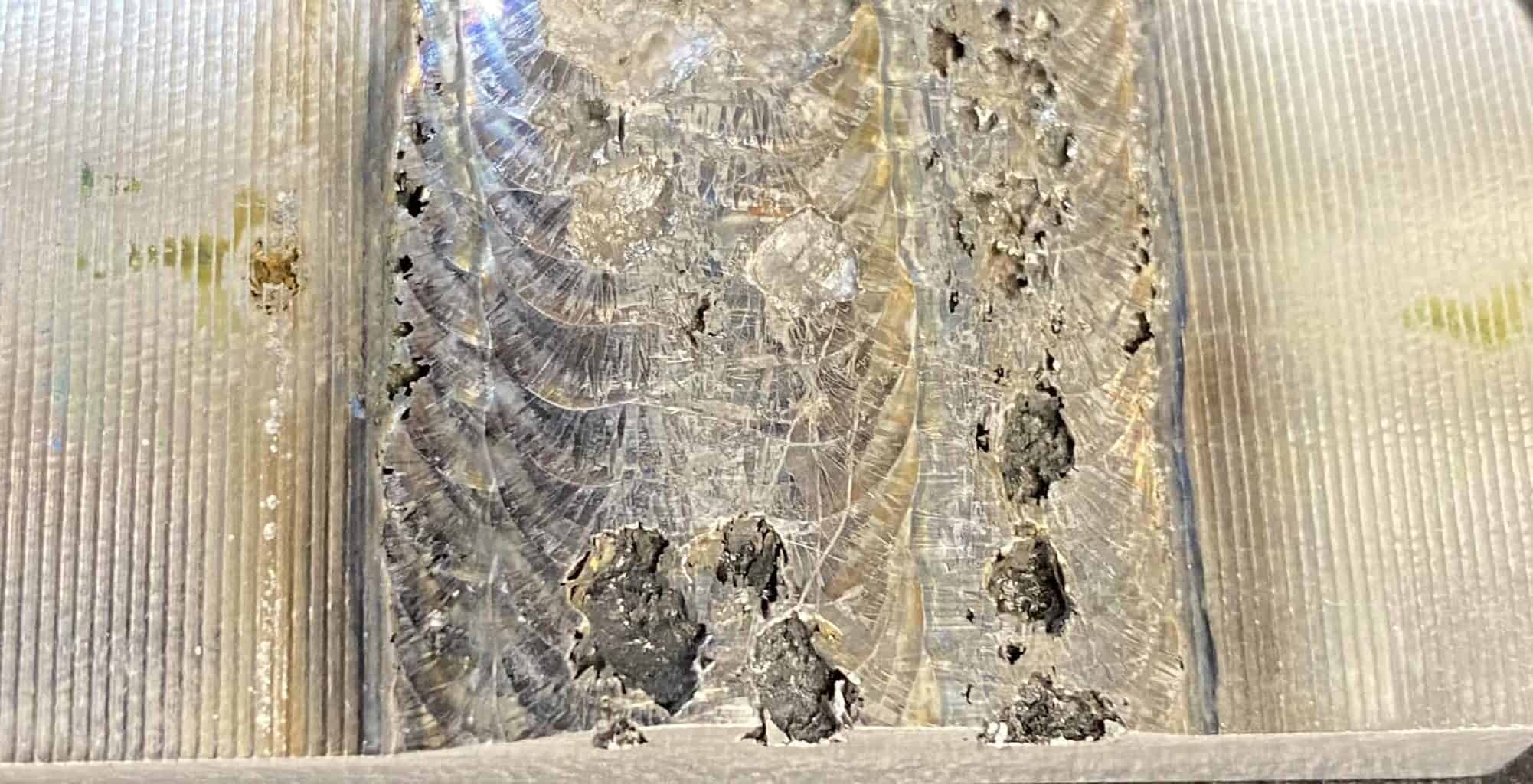

US Corrosion also provides a wide range of welding services from our Houston laboratory; our metallurgists have decades of welding experience. Whether it is development of welding procedures, analysis of welding problems, or failure analysis of welds, we’ve done it all many times. Our Houston welding experts can help you experiment with the best welding procedure, understand the effects of different variables, and ensure you produce with optimal quality (not like below, where severe microstructure damage has made the material susceptible to corrosion).

Welding Corrosion Consulting

Because of their complex nature with many different microstructures present in the weld and heat-affected zones, welds are highly susceptible to corrosion. US Corrosion provides a wide range of consulting services to evaluate welding corrosion, including research and development of welds with minimal corrosion levels, on-site consulting for evaluation of corrosion in existing welds, and failure analysis of weld corrosion that led to a leak or failure.

Welding Failure Analysis Case Study

Welds can fail for a wide range of reasons; our experts can help you pinpoint the root cause, and then develop ways to mitigate it. In the case study below, an improper welding procedure left the weld on this corrosion resistant material subject to erosion over time. The corrosion was found before a leak or rupture could occur in this case but this discovery led to improved inspection of the facility that led to find several other seriously corroded welds that needed replacement.

Weld Qualification and Testing Services

- Welding Consulting and Failure Analysis – Our experts can help determine, understand, and prevent welding failures. Our welding failure analysts help determine the cause of the weld failure and then we evaluate the potential methods to prevent it from recurring.

- Weld Procedure Development – While some welding processes can be developed easily, other require real metallurgical and welding experties. Our welding experts

- Welding research and development (R&D)

- Welding Consulting Services – including welding R&D, procedure development, and corrosion evaluation.

- Welding Quality and Metallurgical Evaluation – metallurgical and microscopic examination, visual inspection, and NDE to evaluate weld quality.

- Weld Procedure Qualification – according to AWS and ASME standard practices and other similar codes.

- Development of Welding Procedures – we can review and/or help you develop new procedures to meet your requirements and applicable codes.

Welding Procedure Development

We also help with procedure development, including optimization of your welding parameters to achieve the optimal weld properties. AWS, ASME, and other common codes can be used for development of your welding procedure specification (WPS). There are several important steps to be followed:

- Evaluate the base material

- Determine the best welding process to be used

- Select the right welding material/consumable

- Determine the right pre-heat and post-heat temperatures if necessary

- Select the right welding gas

- Find and clearly define an acceptable range of welding parameters

- Perform procedure qualification testing

If you really want the best welds, then research and testing can provide much higher quality with better reproducibility. Our metallurgical experts can help you identify and optimize your welds using statistically designed experimentation. We perform a wide range of test welds by experienced welders,

Welding Consulting

Our experts can help solve all kinds of challenging welding issues. Our team brings experience in almost every major industry, including energy, food/beverage, medical, aerospace, transportation, defense, and more. Our involvement can range from simple problem-solving to complex FEA and consulting assessments.

We also work on broader welding consulting projects, such as implementation of ISO welding or ASTM compliant welding procedures across your company, or development of optimized welding parameters. Our experts welders can help your develop repeatable welding procedures that offer solid, consistent results even in challenging situations. By utilizing advanced techniques like residual stress analysis, accelerated corrosion testing, and electrochemical evaluation, along with decades of welding experience, our expert consulting team can help with litigation, production, and R&D.