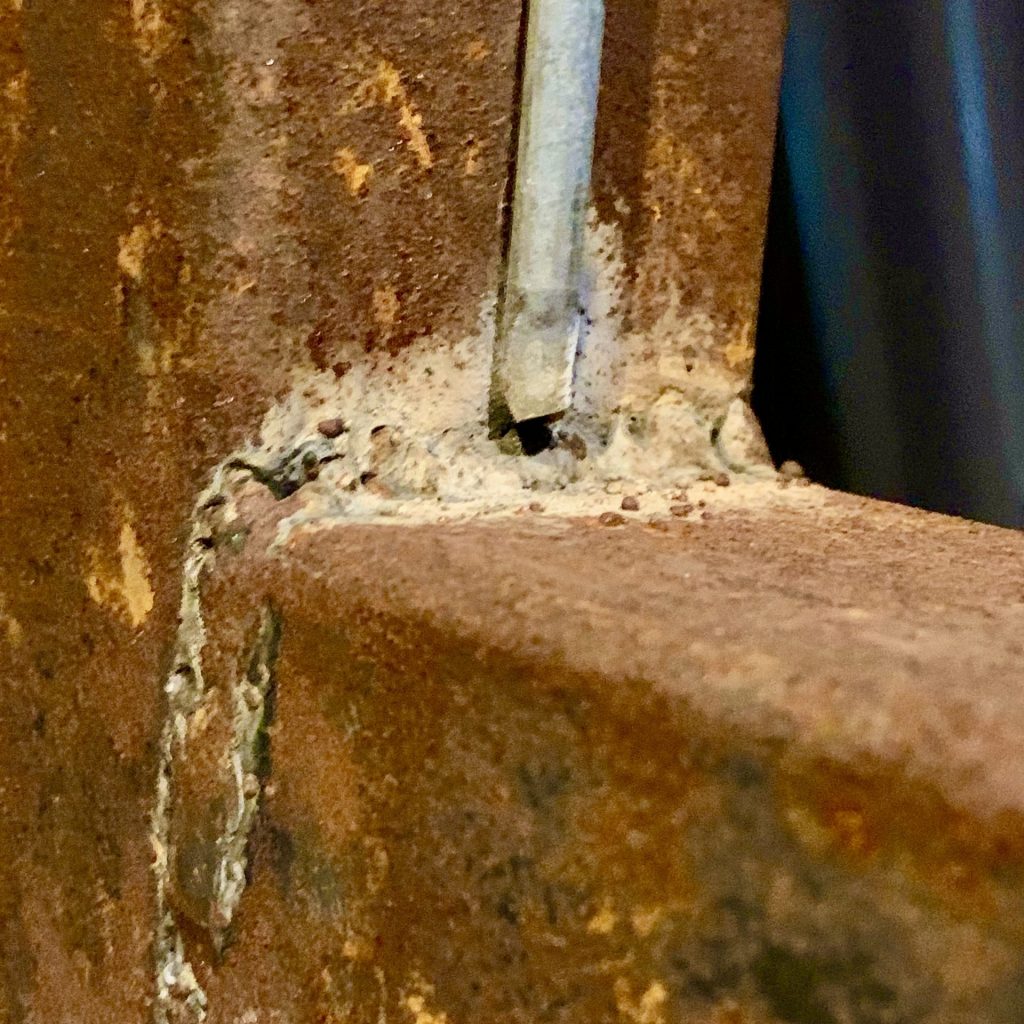

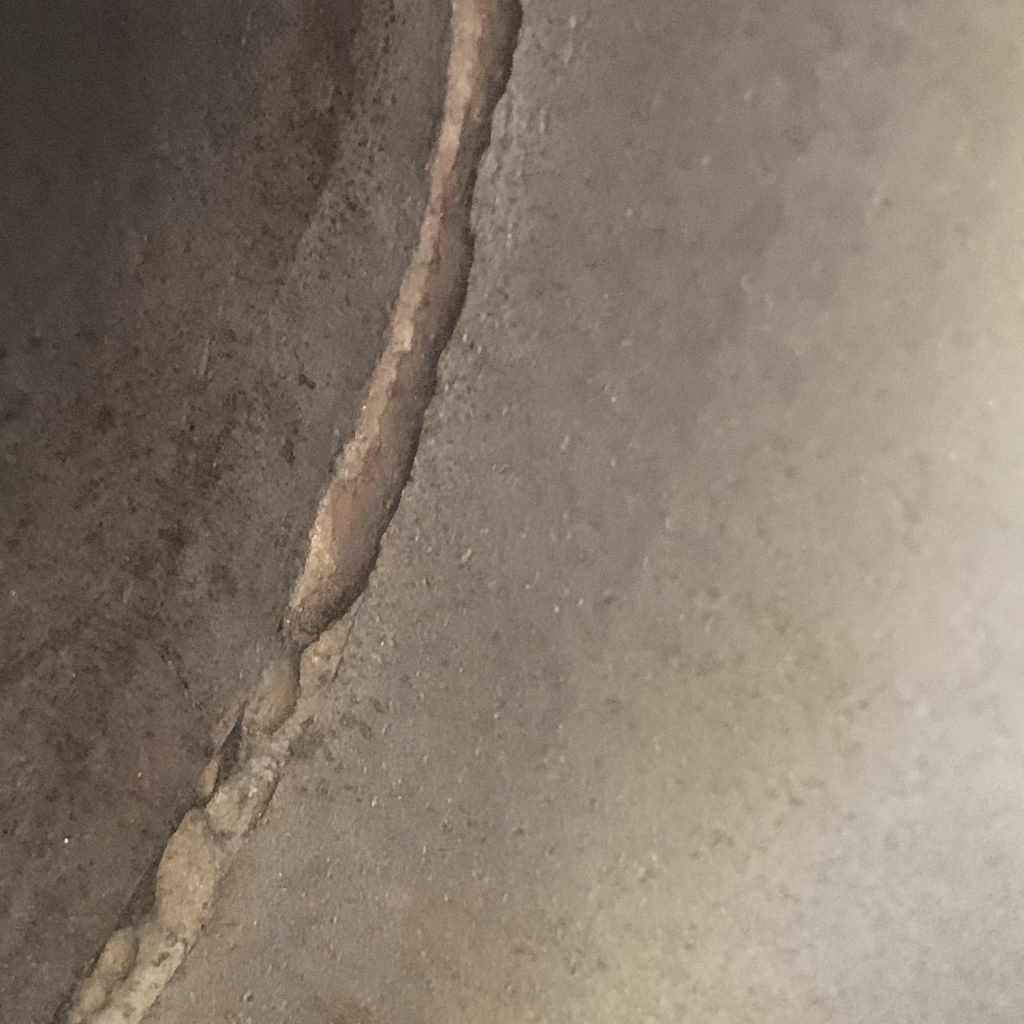

What is Weld Corrosion?

At US Corrosion Services, we understand the critical importance of ensuring the integrity and longevity of welded structures in various industries. Corrosion can be a significant challenge that compromises the performance, safety, and durability of welded components. That’s why we are here to offer comprehensive weld corrosion-related engineering services tailored to meet your specific needs.

Why is Weld Corrosion Engineering Important?

Our team of highly skilled and experienced corrosion engineers specializes in identifying, analyzing, and mitigating the corrosive effects on welded structures. We combine our expertise in metallurgy, materials science, and corrosion prevention techniques to help deliver effective solutions that minimize the impact of corrosion and extend the lifespan of your assets.

Our Approach to Welding Corrosion

What sets us apart is our commitment to providing a holistic approach to weld corrosion engineering. We don’t just focus on treating the symptoms; we dig deeper to understand the root causes of corrosion and develop proactive strategies to prevent its occurrence. Our services encompass:

- Corrosion Risk Assessment: We conduct comprehensive assessments of your welded structures, identifying potential corrosion risks and vulnerabilities. By evaluating factors such as environmental conditions, materials, and design, we provide detailed reports and recommendations to mitigate risks and improve corrosion resistance.

- Materials Selection and Specification: Choosing the right materials for welding applications is crucial to prevent corrosion. Our experts guide you in selecting suitable materials and assist in developing specifications that align with industry standards and best practices. We consider factors such as corrosive environments, temperature variations, your specific application needs, and mechanical stresses to ensure optimal performance and longevity.

- Welding Procedure Development: Our team develops welding procedures that incorporate corrosion-resistant techniques, ensuring that the welded joints are robust and protected against corrosion. We take into account factors such as welding processes, filler materials, pre/post-weld heat treatments, and surface preparation to deliver high-quality, corrosion-resistant welds.

- Coating and Surface Protection: Coatings and surface treatments play a vital role in preventing corrosion. We help you choose the right protective coatings, such as paints, inhibitors, or galvanic coatings, based on your specific application requirements. Our experts ensure proper application techniques and evaluate coating performance to enhance corrosion resistance and extend service life.

- Failure Analysis and Corrosion Investigations: When corrosion-related issues occur, our team conducts thorough failure analysis and corrosion investigations. We identify the causes of failure, assess the extent of damage, and recommend appropriate corrective actions. Our goal is to prevent future failures and enhance the reliability and performance of your welded structures.

- Training and Consultancy: We offer training programs and consultancy services to empower your team with the knowledge and skills needed to understand and manage weld corrosion effectively. Our workshops cover topics such as corrosion fundamentals, preventive measures, inspection techniques, and maintenance strategies. We work closely with you to develop customized training programs that address your specific requirements.

At US Corrosion, we are dedicated to delivering exceptional Weld Corrosion Engineering Services that protect your investments, reduce downtime, and ensure the longevity of your welded structures. Trust our expertise to safeguard your assets against the damaging effects of corrosion. Contact us today to discuss your specific needs and let us be your partner in combating weld corrosion.

Methods for Preventing Weld Corrosion

Ready to get started? Reach out today!