Fast, Accurate Stress Measurement by Hole Drilling

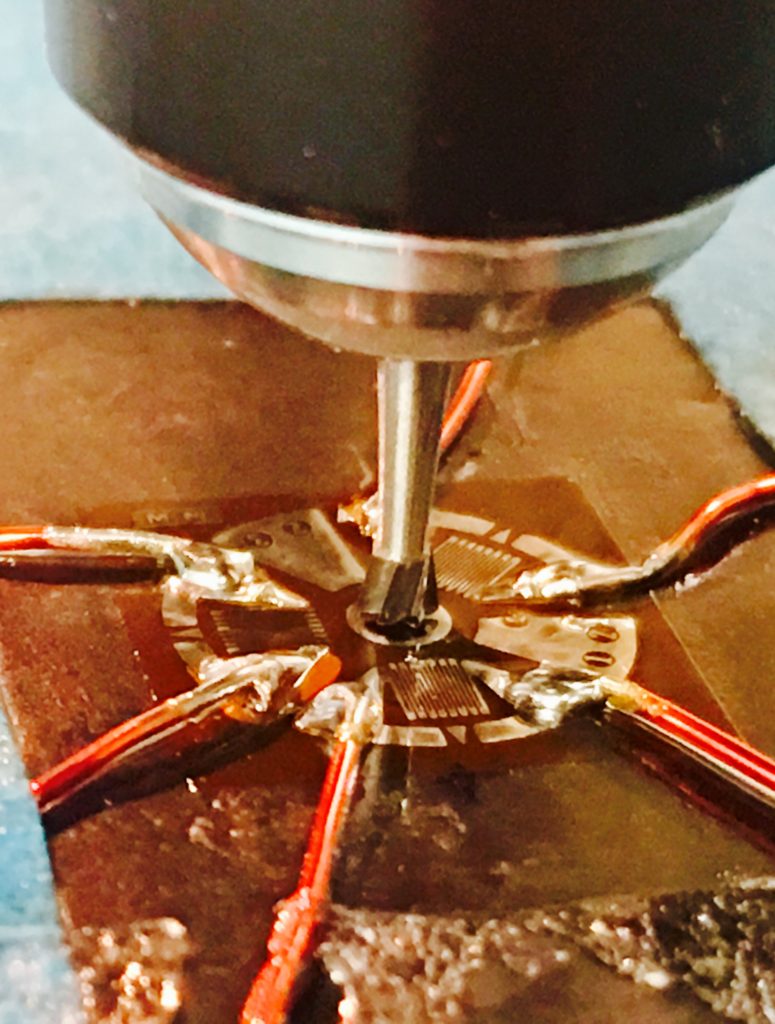

Every material has residual stresses – they accumulate from the fabrication, casting, welding, and installation – and have dramatic influences on the susceptibility to corrosion and cracking. Fortunately, the ASTM E837 method provides a rapid and accurate method to determine the stresses in a semi-destructive manner. A small hole is drilled, with strain gauges at the edges that are monitored as the hole is drilled deeper. From the strain gauge measurements, a calculation of the stresses can be me made that includes the tensile/compressive forces, torque, and more.

What is Residual Stress Analysis?

Residual stresses are those stresses that remain in a material even when there is no external load or thermal gradient present. They can have significant impacts on material performance, affecting fatigue life, dimensional stability, and resistance to fracture or corrosion.

The hole drilling method is a well-recognized technique to measure residual stresses. By drilling a hole into the material, the previously constrained material is free to deform, relieving some of the residual stress. This deformation is then measured and used to calculate the residual stress in the material.

How can Residual Stress be Measured?

Residual stresses can be a major factor in the failure of a material, particularly one subjected to alternating service loads or corrosive environments. For example, the outer edges of welds are subject to extreme tensile stresses from the cooling of the weld. Residual stress may also be beneficial, for example, the compressive stresses produced by shot peening. The hole-drilling strain-gage technique is a practical general-purpose method for determining residual stresses.

Testing by ASTM E837 for Residual Stress Determination

The ASTM E837 method is a precision process for evaluating residual stress in a wide range of materials. The ideal material has a consistent surface morphology with a flat surface and linearly elastic stress; but that’s not the real world, so we can help you understand and evaluate materials of all kinds. If you want to understand residual and dynamic stresses, our team can help.

Why Choose US Corrosion Services?

- Expertise: Our team of skilled engineers and technicians have extensive experience in performing residual stress measurements using the hole drilling method.

- Precision: We use state-of-the-art equipment to ensure accurate measurements and detailed reports for our clients.

- Comprehensive Services: Beyond residual stress analysis, we offer a wide range of corrosion services. Explore our Services Page to find out more.

Frequently Asked Questions (FAQs) about Residual Stress Analysis:

- How long does the residual stress analysis take? The duration can vary depending on the sample size and complexity. Typically, the analysis can take anywhere from a few hours to a couple of days.

- Can this method be applied to all types of materials? While the hole drilling method is versatile, it’s most commonly applied to metals and some non-metallics. If you have specific material questions, contact our team for guidance.

- How does this method compare to other residual stress analysis methods? The hole drilling method is particularly advantageous for its simplicity, cost-effectiveness, and depth resolution.