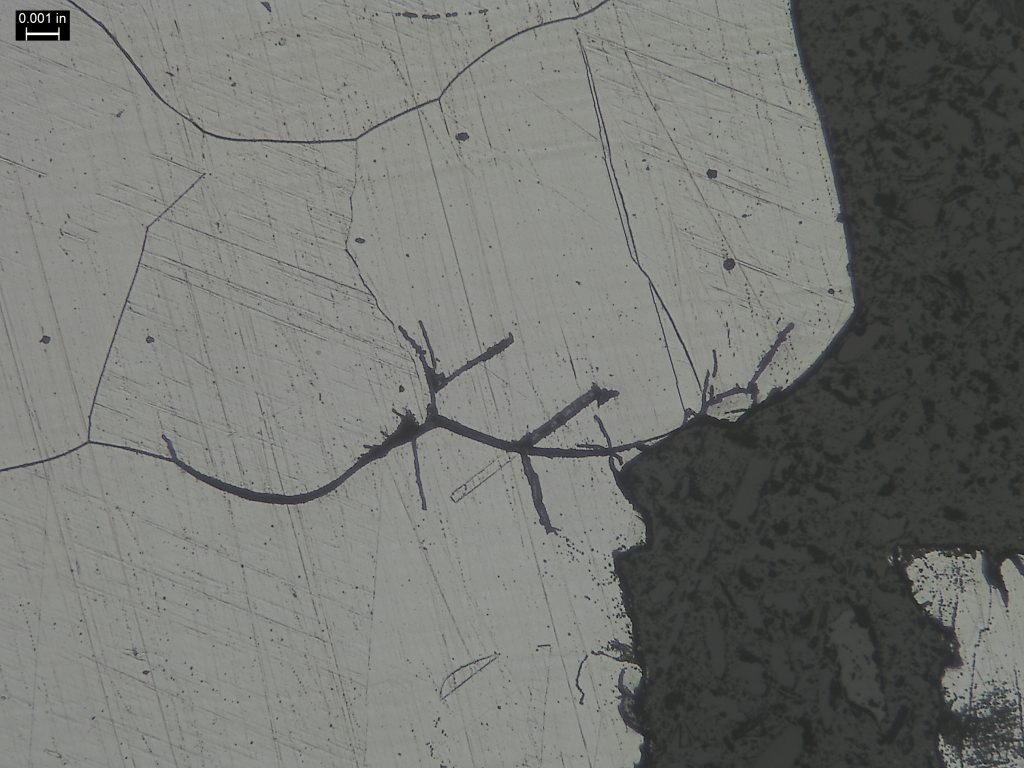

Corrosion analysis and failure analysis go hand-in-hand. One is used beforehand to prevent failures, and the other is used after a failure occurs to find ways to prevent further occurrences. The metallurgists at US Corrosion have decades of experience in metallurgical failure analysis, usually dealing with corrosion in one way or another. In the example below, stress corrosion cracks were observed growing into the sensitized grain boundaries of a stainless steel material:

Where can I get an expert witness for a metallurgical failure analysis case?

If you are dealing with a metallurgical failure analysis case, US Corrosion can provide valuable expertise as an expert witness. US Corrosion experts are highly trained and experienced in the field of corrosion and metallurgy, and can bring specialized knowledge to your case.

US Corrosion experts perform a detailed analysis of the failed component using advanced techniques such as scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), and X-ray diffraction (XRD). This analysis can help identify the root cause of the failure and provide recommendations for preventing future failures.

In addition, US Corrosion experts can provide technical analysis and expert testimony in legal disputes related to metallurgical failure, such as product liability cases or insurance claims. We can help you understand the technical aspects of the case and provide a clear and concise explanation of the failure mechanism, making complex scientific concepts accessible to a non-technical audience.

US Corrosion experts have experience working with a wide range of industries, including aerospace, automotive, marine, and oil and gas. This broad expertise allows us to apply their knowledge to a variety of cases and provide customized solutions to meet your specific needs.

Overall, US Corrosion experts can bring significant value to your metallurgical failure analysis case by providing specialized knowledge and expertise, performing detailed analysis, and providing technical analysis and expert testimony. By working with US Corrosion, you can gain a deeper understanding of the failure mechanism, develop effective strategies for preventing future failures, and make more informed decisions about how to protect your assets and mitigate risks.

What’s included in a failure analysis investigation?

We’ll start with a consultation to determine the scope of the failure and what is needed to investigate it properly. Then we’ll develop a quote with options for turnaround time, the scope of the failure investigation, and different reporting options. Typically, the analysis will include some combination of testing such as:

- Chemical analysis through processes like optical emission spectroscopy (OES), energy dispersive x-ray spectroscopy (EDS), and x-ray diffraction (XRD),

- Fracture surface analysis in the scanning electron microscope and/or stereo microscope by an experienced metallurgist,

- Mechanical testing to confirm the mechanical properties with tensile testing, charpy impact testing, fracture toughness analysis, and/or hardness testing,

- Non-destructive testing (NDT) to look for cracks, defects, or other indications using x-ray, dye penetrant, ultrasonic, eddy current, and other techniques.