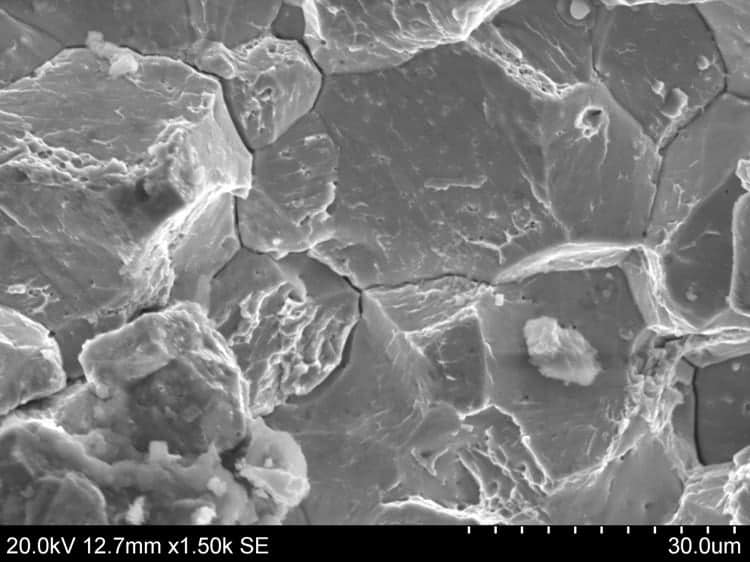

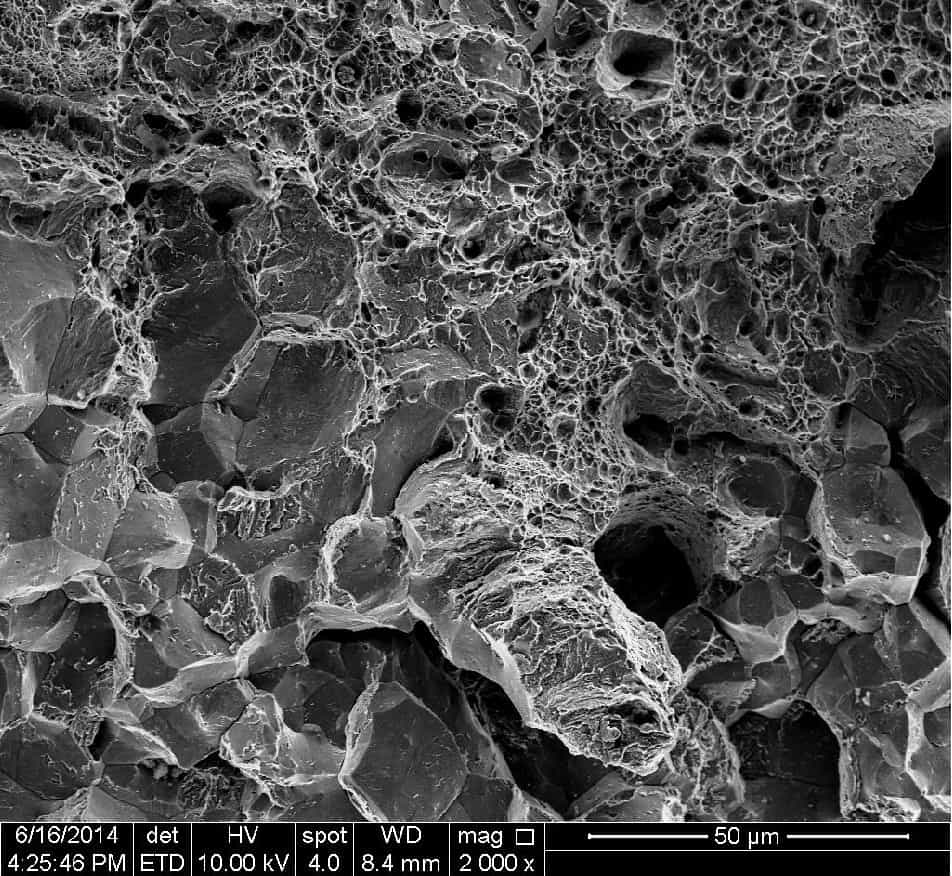

Hydrogen embrittlement failures cause billions of dollars in lost revenues and maintenance costs every year. Our experts can help you evaluate and confirm if hydrogen embrittlement or other causes were to blame, and then develop appropriate mitigation plans to prevent it from happening again. In the example below, the intergranular nature of the cracking is one of the most common hallmarks of hydrogen embrittlement.

Understanding and Preventing Hydrogen Embrittlement

Hydrogen embrittlement is a type of failure that can occur in materials exposed to hydrogen gas or hydrogen-containing environments. It is a complex and sometimes unpredictable phenomenon that can cause catastrophic failures in high-strength materials, such as steel alloys and titanium. Understanding and preventing hydrogen embrittlement is crucial for ensuring the safety and reliability of critical components in a wide range of industries.

Hydrogen embrittlement occurs when atomic hydrogen diffuses into the material and interacts with the microstructure, causing changes in the material’s mechanical properties. This can lead to cracking, fracture, and ultimately, failure of the component. Hydrogen embrittlement can occur during manufacturing, processing, or in-service use, and can be caused by a variety of factors, including exposure to high-pressure hydrogen gas, exposure to hydrogen-containing chemicals, and cathodic protection systems.

Image from Semantics Scholar

Preventing hydrogen embrittlement requires a comprehensive approach that includes material selection, design optimization, and preventative measures. US Corrosion is a leading provider of corrosion and metallurgical consulting services, and they have extensive expertise in understanding and preventing hydrogen embrittlement.

US Corrosion’s experts can provide guidance on material selection and design optimization to minimize the risk of hydrogen embrittlement. They can also perform testing and analysis to evaluate the susceptibility of materials to hydrogen embrittlement and identify potential failure points. US Corrosion’s experts can provide recommendations for preventative measures, such as coatings, surface treatments, and cathodic protection systems, to minimize the risk of hydrogen embrittlement in service.

Overall, understanding and preventing hydrogen embrittlement is critical for ensuring the safety and reliability of critical components in a wide range of industries. US Corrosion’s expertise in corrosion and metallurgical consulting can help manufacturers identify and mitigate the risk of hydrogen embrittlement, ensuring the quality and reliability of their products.

Houston Hydrogen Embrittlement Testing Services

Our laboratory headquarters in Houston offer numerous ASTM Hydrogen Embrittlement tests and custom tests, including:

- ASTM F519 – The aerospace standard for confirming coating processes are not embrittling.

- ASTM F1624 – The incremental step load process for quantitatively measuring HE in real components, both due to processing and from environmental exposure.

- ASTM F1940 – For hydrogen embrittlement analysis of fasteners.

- ASTM B577 – For measuring hydrogen embrittlement of copper alloys.

- Accelerated environmental cracking tests.