Houston Failure Analysis Laboratory

Whether corrosion is the cause or not, we have extensive failure analysis capabilities to help you determine what happened and how to fix it! Our failure analysis services are customized to suit your needs. We do work from ‘quick and dirty’ troubleshooting with verbal or email discussion to a full, detailed scientific reporting suitable for courtroom testimony. We also provide expert witness services for many corrosion and metallurgy topics. Whether you have a full fracture or just a component not performing as expected, we can help you understand and solve the problem. Examples of our work from different projects are shown below:

Our Approach: A Step-by-Step Process:

- 1. Preliminary Inspection: Visual examination of the failed component to gather initial information along with a survey of questions to you that help us understand the failure.

- 2. Root Cause Investigation: Detailed analysis using advanced techniques like Scanning Electron Microscopy (SEM), X-ray diffraction (XRD), and more.

- 3. Mechanical and Chemical Testing: Evaluating material properties and environmental conditions that contributed to the failure.

- 4. Conclusion and Recommendations: A comprehensive report with the root cause of the failure and corrective actions. We work with you to find a solution that’s best.

Technology & Methods:

- Highlight the tools and methodologies used in failure analysis (e.g., SEM, EDS, fractography, metallography).

Failure Analysis Case Study

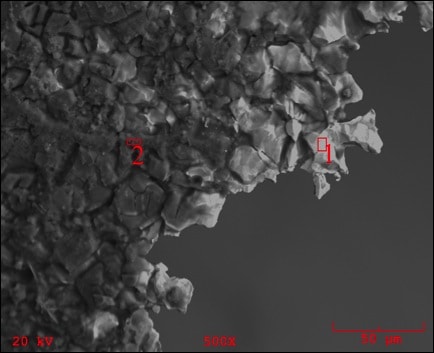

In the example below, energy-dispersive x-ray spectroscopy (EDS) was performed in the SEM on the fracture surface at localized areas to evaluate the chemicals present. Very high levels of chlorine were found, which had led to severe pitting corrosion of this type 304 stainless steel. Ultimately, our recommendations to change to a more corrosion-resistant alloy have prevented any further corrosion failures in this equipment.

How Much Does Failure Analysis Cost?

Failure analysis pricing – Failure analysis cost varies dramatically depending on the length and breadth of the reporting. For quick analysis with email report, the failure analysis price can range from $1500-$4,500. For full reports, the price can be anywhere from $3K-20K+ depending on how much work and consulting analysis required. We also provide follow-on services such as integrity management program development, fitness-for-service assessment, cathodic protection engineering, and inhibitor assessments. Ultimately, our aim is to help you find the answer within your budget, and to prevent problem from recurring.

. Types of Failures Analyzed:

- Mechanical Failures:

- Examples: Fractures, fatigue failures, creep failures.

- Corrosion Failures:

- Types: Pitting corrosion, stress corrosion cracking, galvanic corrosion.

- Material Failures:

- Degradation due to poor material selection or manufacturing defects.

- Thermal Failures:

- Failures caused by overheating, oxidation, and thermal fatigue.

- Electrical Failures:

- Analysis of electrical systems, connectors, and circuits that have experienced failure.

We tailor our services to your needs. Sometimes, it is necessary that the analysis be very thorough, with all aspects to be evaluated as reasonably possible. Other times, a limited scope analysis is all the support that is needed. Below is an outline of common types of investigations.

Failure Analysis Report Options

- Email Summary: Informal investigation with findings provided via email. Minimal discussion in report and minimal consulting time budgeted.

- Summary of Findings: Short report that includes findings and some discussion. Some consulting time is included.

- Full Report: Thorough failure analysis report including documentation of laboratory findings and a discussion of the results and failure mechanism, conclusions, and recommendations when possible.