Testing for External Hydrogen Embrittlement

US Corrosion offers ASTM F2660 testing for external hydrogen embrittlement. Specifically, we use the rising step load method from ASTM F1624 and apply it for A490 bolts with coatings, helping to ensure they are not susceptible to external hydrogen embrittlement.

How Does ASTM F2660 Testing Work?

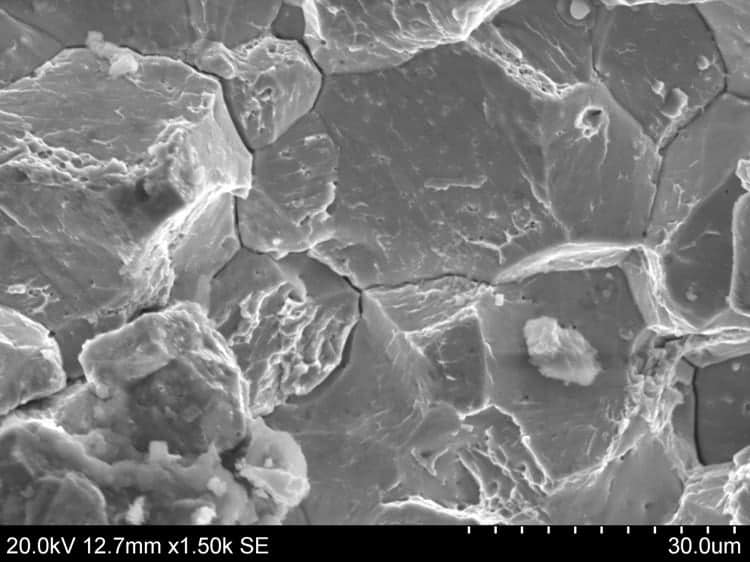

In metallurgy, ASTM F2660 testing provides a standardized method for evaluating the susceptibility of metallic materials to hydrogen embrittlement. The testing involves subjecting the specimen to a controlled hydrogen charging process followed by mechanical testing, allowing for the assessment of the material’s resistance to hydrogen-induced cracking and its overall structural integrity.

How Many Samples Are Tested in F2660?

In ASTM F2660, the number of samples tested may vary depending on the specific requirements and objectives of the test. Typically, multiple samples are evaluated to gather statistically significant data, ensure repeatability, and account for any variations or outliers that may occur during testing.

How Long Does F2660 Testing Take?

First, ten fast-fracture tensile tests are performed. Inclusive of machining, this can take 1-4 days to complete. Then a minimum of 5 step loading tests are performed, where 10 2-hour steps (from 0 to 50 %) are followed by 10 4-hours steps (from 50 % to 100 % or whenever a crack is detected). Overall, each test takes up to 3 days to complete. The testing loads are then adjusted based on the previous test, requiring all tests to be performed in series. The total estimate time span is a minimum of 16 business days just in testing time. Each coated sample is tested either with an applied cathodic voltage (as seen below) or in the freely corroding condition.