Electron Microscopy Testing and Analysis in Houston and Beyond

Houston Electron Microscopy Services:

US Corrosion offers a number of advanced analytical microscopy techniques, the most of common of which is electron microscopy. In the scanning electron microscope (aka SEM), a beam of electrons is used as the light source instead of visible light. Because the wavelength of electrons is around 100,000 times smaller than photons, the electron microscope is capable of going to very high magnifications for analysis. When combined with the chemical analysis tools such as EDS, the SEM allows for super high precision analysis of materials down to the sub-micron level.

How does Electron Microscopy Work?

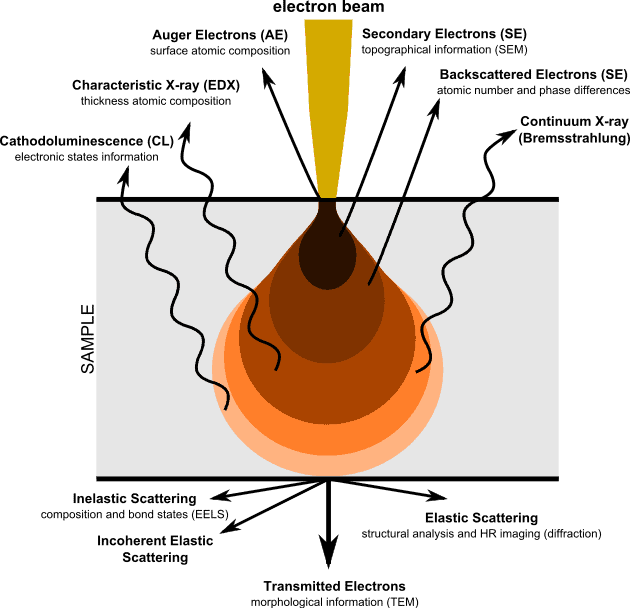

Electron microscopes use a beam of electrons that have been accelerated and focused on a tiny area, and then measure the electrons or X-rays that are emitted from the surface of the material. This is shown below including several forms of emission that occur.

Our Houston Electron Microscopy Laboratory Facility:

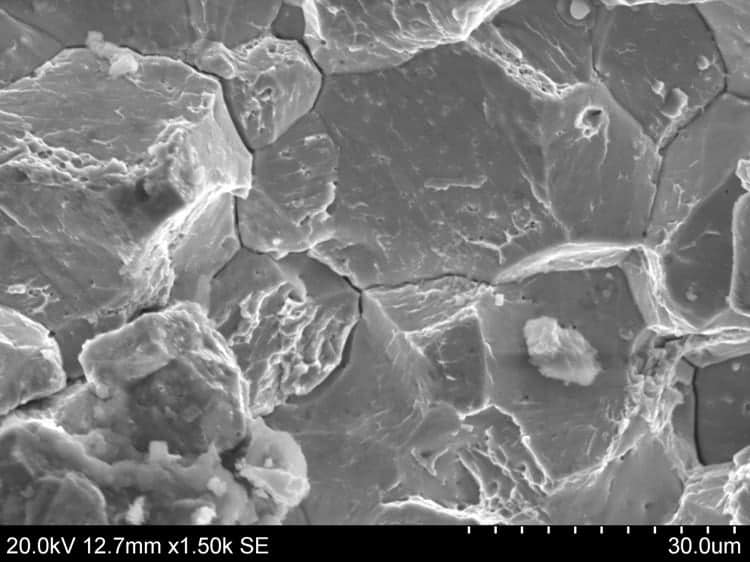

For example, the electron microscope in our Houston electron microscopy laboratory is often used for failure analysis. In the case below, a sample suspected of failure by hydrogen embrittlement was evaluated to determine the nature of the fracture surface (a practice known as fractography). The intergranular fracture seen is a clear indicator of hydrogen embrittlement:

Localized Chemical Analysis in the SEM

SEM images can tell you a lot, but most modern systems also often include one or several types of additional analyzers for local chemical and crystal structure analysis. These tools can help separate and map the chemical or crystal structures of anything visible in the SEM, although they generally work better on metals and organic materials than polymers or ceramics. We use the combined SEM and chemical data for analysis such as:

- Fractography of failed components, where we study the cracked area to evaluate they it occurred,

- Analyzing residues on corroded or damaged components,

- Confirming or evaluating hydrogen embrittlement and other types of failures,

- Testing contaminants from plastics, foods, and medical processes or products,

- Evaluating carbides, precipitates, sensitization, and other microstructure features, and

- High-resolution analysis of field metallurgical replica samples taken in-situ.

Our Houston SEM testing capabilities include energy dispersive X-ray spectroscopy (EDS), wavelength dispersive X-ray spectroscopy (WDS), and electron backscatter diffraction (EBSD), three powerful chemical and crystal structure analysis tools. Each has its own special set of capabilities, which are described in more detail below:

What is EDS?

Energy dispersive x-ray spectroscopy (often called EDS or EDX) measures the energy of x-ray’s being emitted by the atoms being analyzed. A high-energy beam of x-rays strikes the atoms, bumping electrons out of their ground state shell. When this happens, other electrons falls from higher shells to take the empty spot, and in doing so emit an x-ray whose wavelength is equivalent to the energy difference between the two shells. The unique atomic structure of each elements results in a characteristic spectra being developed, and analysis software is then used to determine the percentage of each element present. The EDS detector measures the emitted x-rays, converting them into a graph based on energy (in KeV) like this:

From this spectra, analytical software can be used to determine the semi-quantitative elemental composition. Due to the overlap that occurs between some elements (where the peaks are in nearly the same position), it is important to have a skilled electron microscope operator who can determine which element is more likely to be present. In addition, we have an extremely diverse set of calibration standards that can be used to further improve the accuracy of our chemical element measurements. The data is tabulated in both atomic and weight percent, like so:

What is WDS?

Similar but different: wavelength dispersive x-ray spectroscopy evaluates the wavelength of x-rays to determine the elements from which the are emitted. WDS also generates a spectra, which is evaluated using Bragg’s law to determine the wavelength of each emitted x-ray. These can again be evaluated based on their connection the atomic structure to produce spectra and to determine the elements present. WDS provides superior spectral resolution, but takes substantially longer so in most cases EDS is preferred for faster analyses.

What is EBSD?

EBSD is a powerful technique for evaluating the crystal structure of metals and other crystalline materials. It is often used for advanced metals and alloys, such as turbine blades and other shape-sensitize materials.

What other chemical analysis techniques do you offer?

We provide a wide range, including XRD, FTIR, XPS, and more! Together, they can evaluate metals, plastics, concretes, rocks, hydrocarbons, surfaces, and more. Some techniques provide details on the elements present, while others (like XRD) can determine which compounds are involved. Contact us if you need help determining the right chemical analysis tool for your application.

Where can I get electron microscope analysis in Houston?

Our Houston electron microscopy lab is located at 8307 Kempwood Dr. in Houston, just off of Hempstead Hwy in the northeast corner of town. We offer inexpensive sample pickup and delivery services, and rapid testing capabilities. When you need rush SEM analysis, we can often get your samples analyzed and reports generated on a same-day or next-day basis (depending on time of receipt and analysis needed).

What is the Cost of Scanning Electron Microscopy:

Our pricing starts at $350/hour, including an experienced SEM technician to operate the scope. Alternatively, we can provide an expert-level PhD metallurgist to operate the scope and provide real-time feedback for both on-site and remote analysis for $475/hour. US Corrosion also provides extensive other services including mechanical testing, sample preparation, chemical analysis, consulting, and failure analysis – for more detailed price info on SEM or other services, please get in touch.

Why Trust US Corrosion Services?

- State-of-the-Art Equipment: We utilize the latest electron microscope technology ensuring crisp, detailed images and precise data.

- Experienced Team: Our analysts bring years of expertise to each project, ensuring accurate and actionable insights.

- Tailored Analysis: Every client’s needs are unique – we customize our approach to deliver targeted results.

- Fast Turnaround: When urgent results are needed, we ensure timely analysis without compromising on quality.