Is wear and tear eating into your equipment’s lifespan and your bottom line?

Whether you’re dealing with mining equipment, oil field components, or industrial machinery, abrasion and erosion can turn profitable operations into costly maintenance nightmares. That’s where our ASTM G65 dry sand abrasion testing comes in, and its why companies across Houston and around the world trust US Corrosion to help them make smarter material decisions.

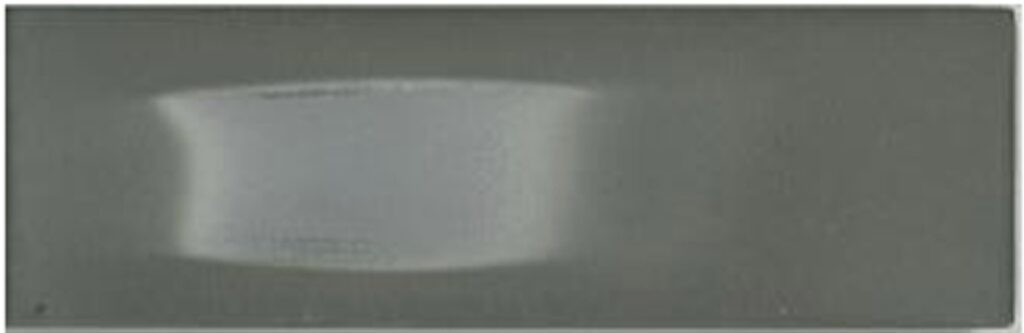

Abrasion and erosion are common challenges in many industries, especially those that involve heavy machinery and equipment. To ensure the durability of materials and components, it is important to conduct abrasion testing using standardized methods. ASTM G65 is the most commonly used method in industry, where a rubber wheel rubs sand against your metallic or coated coupon, leaving a scar like this:

What are the normal G65 Test Parameters?

ASTM G65 includes five standardized test procedures for measuring abrasion and erosion corrosion resistance of materials; the test is performed under specific conditions of load, speed, and duration with different methods available in G65. These are the five G65 abrasion testing procedures, along with the critical test variables:

Standard Test Procedures:

- Procedure A: 6,000 revolutions, 130 N force, 30 minutes

- Procedure B: 2,000 revolutions, 130 N force, 10 minutes

- Procedure C: 100 revolutions, 130 N force, variable time

- Procedure D: 6,000 revolutions, 45 N force, 30 minutes

- Procedure E: 1,000 revolutions, 130 N force, 5 minutes

Critical Test Variables:

- Wheel diameter: 228.6 mm (9.00 in)

- Wheel hardness: Durometer A-60

- Sand flow rate: 300-400 g/min

- Sand type: AFS 50/70 rounded quartz

- Particle size: 212-300 μm

- Test temperature

However, sometimes you may need to alter those conditions. Our Houston abrasion testing lab can also run modified tests with all kinds of changes – let us know what you have in mind or what your application needs are.

What is ASTM G65 intended for?

Think of ASTM G65 as your material surface’s or coating’s toughness test. This standardized method uses a dry sand/rubber wheel apparatus to simulate real-world wear conditions your materials face every day. We rotate your sample against a rubber wheel while feeding controlled amounts of silica sand between them – mimicking the harsh conditions your equipment endures in the field.

The beauty of this test? It gives you hard data, not guesswork. You’ll know exactly how your materials, coatings, and surface treatments will perform before you invest thousands (or millions) in equipment.

Applications of ASTM G65

G65 is widely used in the automotive, aerospace, mining, and construction industries to evaluate the abrasion resistance of materials and coatings for production or R&D. The test is helpful to confirm that the abrasion resistance is sufficient based on the application. It is used in research and development to evaluate the performance of new materials and coatings.

Links to relevant sources

If you are interested in learning more about ASTM G65 and its applications, the following resources may be helpful:

- ASTM International: The official website of ASTM International provides detailed information on ASTM G65, including the standard test method, the significance and use of the method, and the precision and bias of the results.

- Industry publications: Various industry publications, such as the Society of Automotive Engineers (SAE) International Journal and the International Journal of Abrasive Technology, also feature articles on ASTM G65 and its applications.

- Abrasion Resistance of Materials – M Adamiak, 2012.

- Tribology: Friction and Wear of Engineering Materials, 2nd Edition, Ian Hutchings.

ASTM G65 is a widely used method for evaluating the abrasion resistance of materials and coatings. By using this standardized method, engineers and researchers can ensure that the test results are consistent and reliable, enabling them to make informed decisions about material selection and design.

What other relevant tests are used?

While G65 is the most common test we perform, there are several other alternatives we can also help with, including G75 (wet sand), G76 (particle impingement)

| Standard | Abrasive | Contact Type | Best Application |

| ASTM G65 | ASTM G75 | ASTM G76 | ASTM B611 |

| Dry sand | Wet sand | Gas-entrained | Dry sand |

| Line contact | Line contact | Impingement/Impact | Area contact |

| General screening | Slurry erosion | Erosion resistance | Thermal spray coatings |

Where can I get ASTM G65 testing?

US Corrosion is just off Hwy 290 in the northwest corner of Houston. Our lab welcomes visitors and witnessing of tests with advance notice so we can cover or remove proprietary projects.

ASTM G65 Testing Sample Requirements:

Size: 0.9 to 0.99″ wide × 3″ long × 0.15 to 0.5″ thick

Quantity: Typically 3+ specimens per material lot (more for enhanced statistical confidence)

Turnaround: Fast results when you need them – just let us know your timeline.

We provide G65 testing along with other abrasion tests like pin-on-disk, Taber abrasion, and more. After your ASTM G65 test, we don’t just hand you a number and send you on your way. Our comprehensive characterization services help you understand the complete picture:

- Comparative analysis with industry benchmarks

- Weight loss analysis and wear rate calculations

- Detailed scar measurements and surface profiling

- Metallographic examination to understand wear mechanisms

- Advanced microscopy (SEM/EDS) for failure analysis

- Coating adhesion testing

Can you provide modified testing for different applications?

Our lab offers a range of customized G65 tests at different temperatures or with other variables adjusted to suit your specific needs. We often run these tests at various temperatures, with modified sands, or with other adjustments to meet specific customer needs.

Need a quote or want more info? Contact our team of testing experts now, and please include details of the scope of work, # of samples, temperature, etc as well as how urgent your request is: