Coupons to Fit Your Needs

Here at US Corrosion we are a business that specializes in providing corrosion monitoring solutions for a variety of industries. One of the key components of their corrosion monitoring systems is the use of coupons, which are small metal samples that are inserted into the system being monitored to measure corrosion rates.

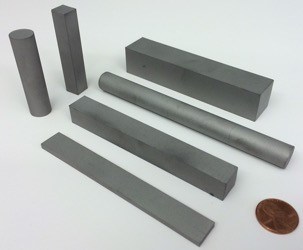

US Corrosion offers a large range of coupons to meet the needs of our clients. These coupons come in a variety of materials, sizes, and shapes, and can be customized to meet specific monitoring requirements. Some of the materials used for the coupons include carbon steel, stainless steel, copper, brass, and aluminum. They can be made from standard cast or wrought materials, or from additive manufacturing as shown below:

The sizes of the coupons can vary depending on the size of the system being monitored and the specific monitoring requirements. US Corrosion offers coupons ranging in size from 1/8 inch to 4 inches, and can provide custom sizes upon request.

In addition to different materials and sizes, US Corrosion also offers different shapes of coupons, including flat, disc, and rod-shaped coupons. The shape of the coupon can be important in certain monitoring applications, as it can affect the measurement accuracy and the ability to detect localized corrosion.

What kind of materials can you make corrosion coupons from?

US Corrosion offers a variety of materials for our corrosion coupons to ensure that we can meet the needs of our clients across different industries. The choice of material for the coupon is typically based on the specific application, the type of corrosion being monitored, and the environment in which the system is operating.

How long does it take?

The amount of time it takes to perform a corrosion couponing test can vary depending on several factors. The primary factors that can affect the testing time include the type of environment being monitored, the type of coupon being used, and the length of time required to obtain accurate corrosion rate measurements.

During the installation process, the coupon is inserted into the system being monitored and allowed to remain in place for a specific period, usually between 3 to 10 business days. This period allows for the coupon to be exposed to the corrosive environment and to experience the same corrosive effects as the system components being monitored.

After the coupon has been in place for the predetermined period, it is then retrieved and analyzed to determine the corrosion rate. The analysis process can take several days to complete, depending on the method used to measure the corrosion rate, as well as the number of coupons being analyzed.

Overall, the length of time required for corrosion couponing can vary depending on the specific application and the needs of the client. At US Corrosion we work with our clients to develop customized corrosion monitoring solutions that meet their specific needs, including determining the optimal testing durations to obtain accurate and useful data.

Corrosion Coupon Analysis and Consulting

We also provide corrosion coupon analysis if you need analysis of your samples after testing. This can range from simple cleaning and weight loss, to thorough electron microscopy, FTIR, XRD, and other chemical analysis.