Corrosion Testing Using Corrosion Coupons

Corrosion coupons are one of the simplest and most common tools in the corrosion engineer’s arsenal. They provide a simple, realistic, and inexpensive method to track corrosion in all sorts of gas and liquid systems. We provide corrosion coupons from Houston, Texas to companies around the world for applications of every kind, along with a wide range of testing capabilities. In addition, we have the deep corrosion expertise to help you interpret the results and determine appropriate next steps.

What are Corrosion Coupons?

Corrosion coupons are small metal samples that are inserted into a system being monitored to measure the rate and extent of corrosion that is occurring. They are widely used in industries such as oil and gas, chemical processing, water treatment, and others to monitor the corrosion of pipelines, tanks, and other equipment.

The coupons are typically made of the same material as the system being monitored, and are exposed to the same environmental conditions as the system components. They are designed to simulate the corrosion that occurs in the system, allowing operators to monitor the corrosion rates and identify potential issues before they become more severe.

Corrosion coupons can come in a variety of shapes and sizes, depending on the specific application. They can be flat, disc-shaped, or rod-shaped, and can range in size from a few millimeters to several inches. The coupons are inserted into the system being monitored and allowed to remain in place for a predetermined period, usually between 7 and 90 days. During this time, they are exposed to the corrosive environment and experience the same corrosive effects as the system components.

After the coupons have been in place for the designated period, they are retrieved and analyzed to determine the extent and severity of the corrosion that has occurred. The analysis can involve visual inspection, weight loss analysis, or electrochemical methods, depending on the specific needs of the application.

Overall, corrosion coupons are an important tool for monitoring corrosion rates and identifying potential issues before they become more severe. They provide valuable data that can be used to optimize maintenance and corrosion prevention programs, and to extend the lifespan of equipment and infrastructure.

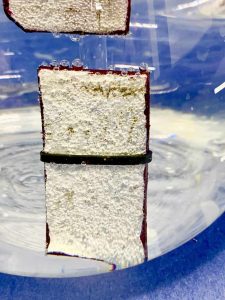

In the images below, a corroded coupon is shown on the left. In the center is a set of three coupons which have been inserted in a flow loop. On the right is an example of immersion corrosion testing of a coupon which is halfway immersed in the liquid:

Metal Corrosion Coupons for Corrosion Testing

Metal corrosion coupons are widely used in corrosion testing to monitor the rate and extent of corrosion that is occurring in a system. They are small metal samples that are designed to simulate the corrosion that occurs in the system being monitored, allowing operators to track the rate of corrosion and identify potential issues before they become more severe.

Corrosion coupons can be made from a variety of materials, including carbon steel, stainless steel, copper, brass, and aluminum. The choice of material for the coupon is typically based on the specific application, the type of corrosion being monitored, and the environment in which the system is operating.

A common question for corrosion coupon testing is this: will any material will work or should you use the actual material from the same heat that you plan to fabricate with? Our suggestion is to always use the closest material you can have, and ideally from the same heat.

Where to Get Corrosion Coupons and Analysis?

US Corrosion is a reputable provider of corrosion coupons and analysis services that can help you detect, monitor, and manage corrosion in your assets. We provide coupons for Houston, Texas, and around the world.

Reasons to consider partnering with US Corrosion for your corrosion monitoring needs:

Coupons from US Corrosion can help provide early detection and quantification of corrosion. Corrosion coupons are small metal samples that are exposed to the same conditions as the equipment or structure being monitored. By regularly measuring the weight loss of these coupons, US Corrosion can detect corrosion early, before it becomes a significant problem. This allows for proactive maintenance instead of reactive repairs, which can save you time and money.

US Corrosion uses standard and advanced analytical techniques to accurately measure the weight loss of the corrosion coupons as well as other attributes of the observed corrosion. This information is used to calculate the corrosion rate of the equipment or structure being monitored. Knowing the corrosion rate allows for more accurate predictions of when maintenance or replacement will be necessary.

We also offer customized corrosion monitoring programs to meet your specific needs. They can help you design a corrosion monitoring program that is tailored to your assets and operating conditions. This ensures that you get the most accurate and relevant data to make informed decisions about your maintenance and repair strategies. Partnering with US Corrosion for your corrosion monitoring needs can help you detect, monitor, and manage corrosion in your assets.

Corrosion Coupons Analysis

Equally important is ensuring that you have accurate analysis after testing. Our corrosion laboratory can help. US Corrosion offers many different corrosion analysis services, ranging from simple weight loss testing to thorough SEM analysis with EDS chemical element mapping. We follow many of the common ASTM corrosion testing standards, including ASTM G31, G1, G28, G48, A262 and many other common industry standards, as well as customized tests for your specific application.

Our experienced engineers have encountered every form of corrosion – and we can help you determine how to test for them, what to do, and how to prevent them. We even offer expert witness services for legal matters should you need them.